Bambu PVA suda çözünebilen bir destek malzemesidir. Karmaşık tasarımlar ve çıkıntılar için güvenilir destek sağlar ve baskıdan sonra suda kolayca çözülebilir. Çeşitli filamentlerle uyumludur, son işlemeyi basitleştirir ve destek çıkarma sırasında basılı nesnenin hasar görme riskini azaltır.

Bambu PVA, suda çözünme, düzenli desteklerin yetersiz kaldığı yerlerde destek sağlamak için karmaşıklıkların derinliklerine nüfuz etme yeteneğine sahiptir. Bambu PVA ile daha önce imkansız olan modelleri tasarlayabilir ve basabilirsiniz.

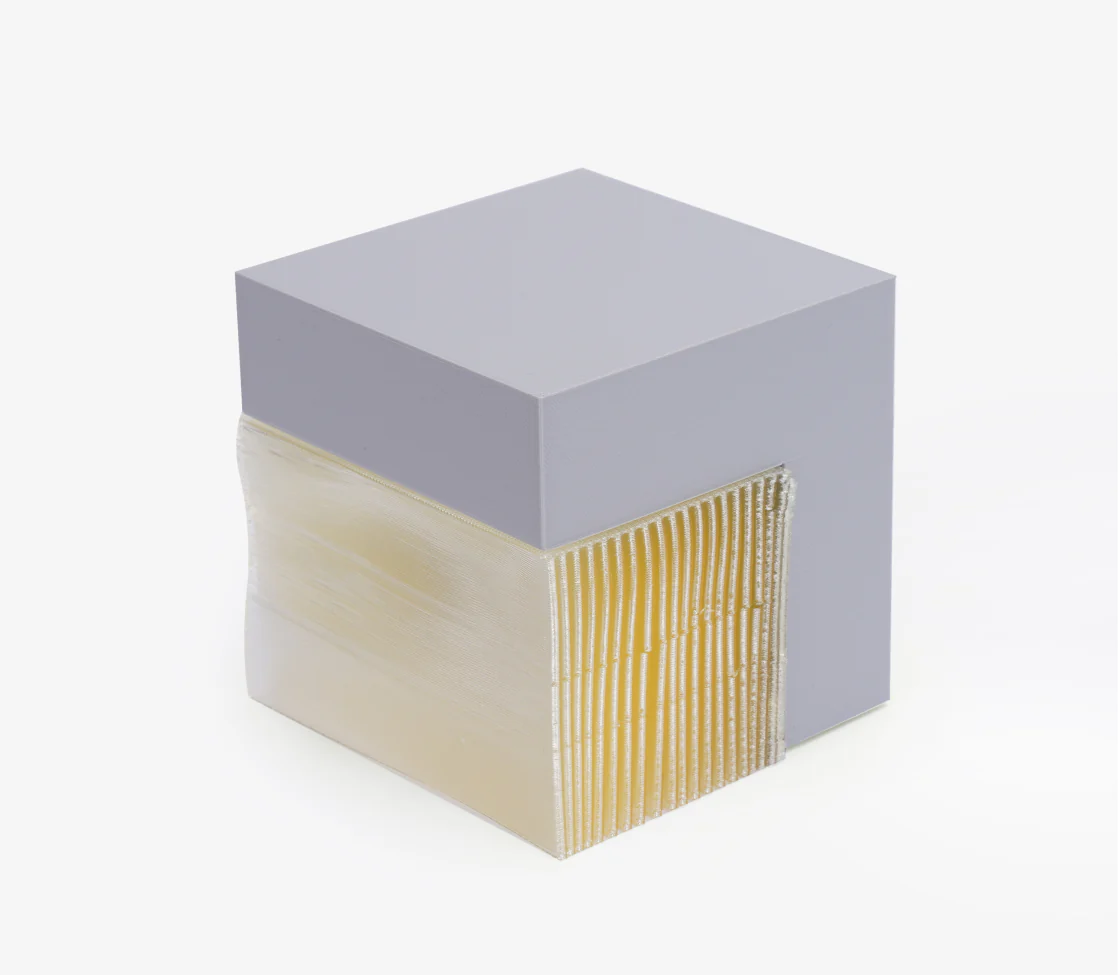

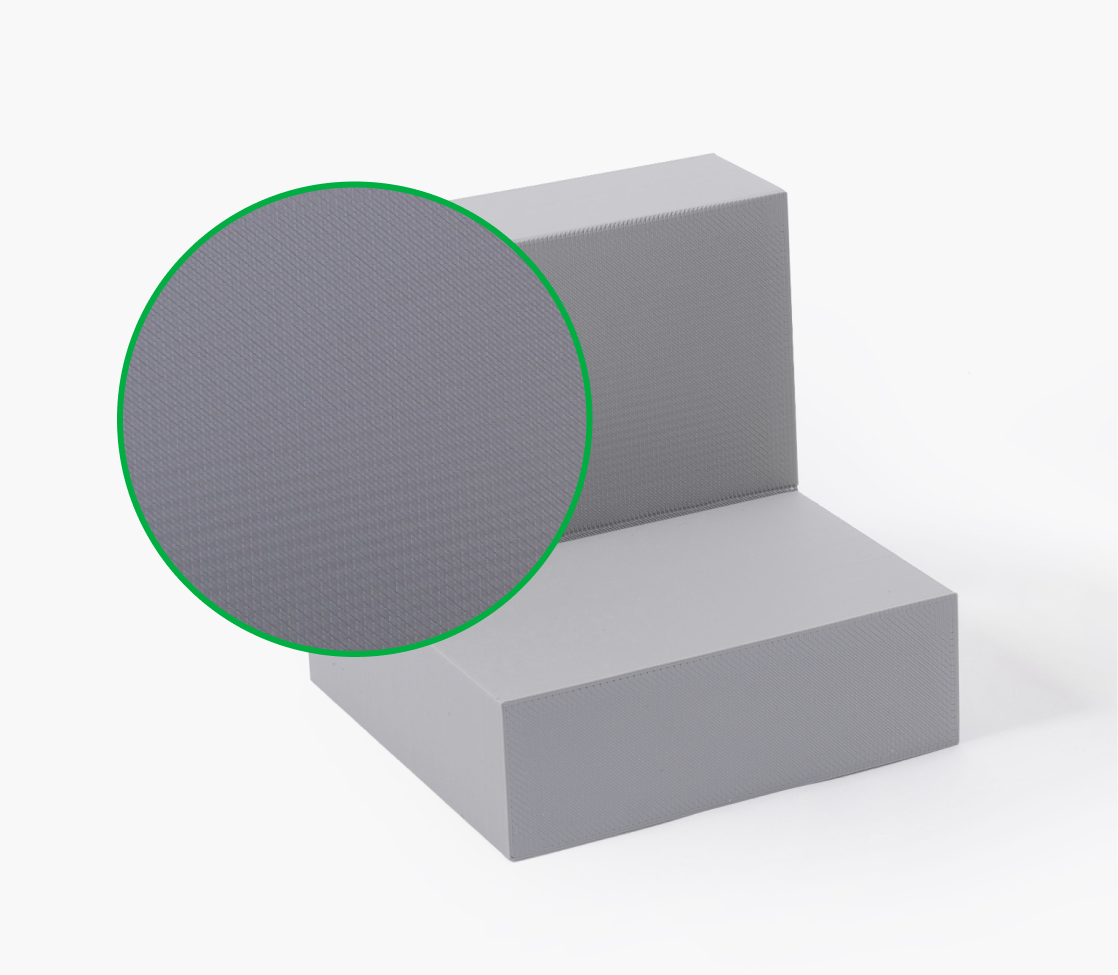

Suda çözünen destek malzemesi, sıfır üst arayüz boşluğuna uyum sağlayarak baskı yüzeyiyle kusursuz bir bağ sağlar ve baskılarınız için hassas ve pürüzsüz destek temas yüzeyleri elde edilmesini sağlar.

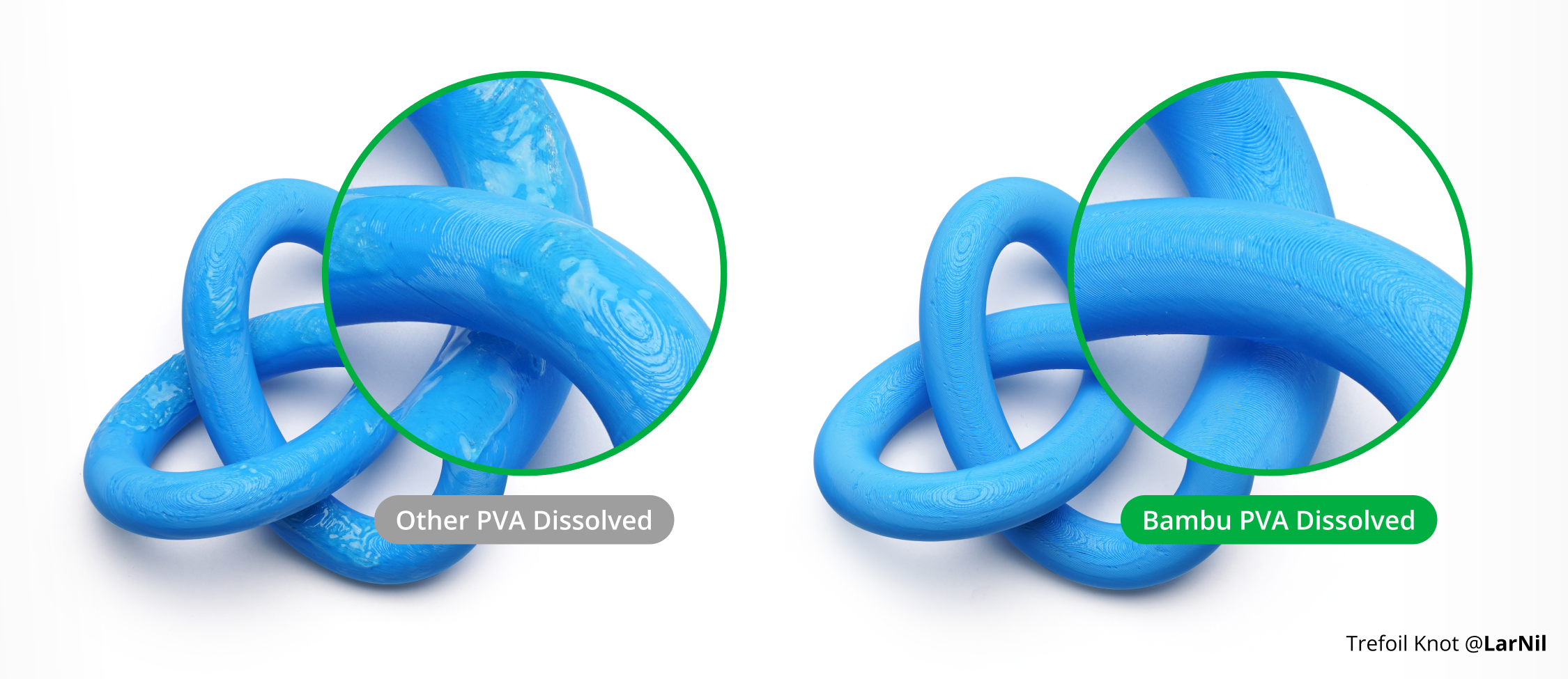

Bambu PVA, suda kolayca ve iyice çözünen, destek malzemesini zahmetsizce çıkaran ve manuel temizliğin zorluğunu ortadan kaldıran yüksek kaliteli bir formül kullanır.

| PVA | PLA'ya Destek | PA/PET desteği | |

| Uyumluluk | PLA, PETG, PLA-CF/GF, PETG-CF/GF | PLA, PLA-CF/GF | PA, PA-CF/GF, PA6-CF/GF PAHT-CF/GF, PET-CF/GF |

| Nozul Uyumluluğu | Tüm Boyutlar / Malzemeler | 0.2 mm Nozul Uyumlu Değil | |

| Çözünürlük | Suda çözünebilir | Suda çözünmeyen | |

| Tavsiye edilen | Tavsiye Edilmez | |

| Yapı Plakası | Soğuk Plaka, Yüksek Sıcaklık Plakası veya Dokulu PEI Plakası | Mühendislik Plakası |

| Sıcak uç | Tüm Boyutlar / Malzemeler | / |

| Zamk | Bambu Sıvı Tutkal / Tutkal Çubuğu |

| Renk | Hex Kodu | Görüntülemek | |

| Temizlemek | #F0F1A8 | ||

Tüm baskı parametreleri, AMS (Otomatik Malzeme Sistemi) aracılığıyla okunabilen RFID'ye yerleştirilmiştir.

Yükleyin ve yazdırın! Artık sıkıcı ayar adımları yok.

| Önerilen Yazdırma Ayarları | |

| Kurutma Ayarları (Fırınlamalı Kurutma) | 80 °C, 12 saat |

| Baskı ve Konteynerin Nemini Koruma | < %20 RH (Kapalı, Kurutucu ile) |

| Nozul Sıcaklığı | 220 - 250 °C |

| Yatak Sıcaklığı (Tutkallı) | 35 - 45 °C |

| Baskı Hızı | < 200 mm/s |

| Fiziksel Özellikler | |

| Yoğunluk | 1,27 gr/cm³ |

| Vicat Yumuşama Sıcaklığı | Yok |

| Isı Sapma Sıcaklığı | Yok |

| Erime Sıcaklığı | 202 °C |

| Erime İndeksi | 7,2 ± 1,1 g/10 dak |

| Mekanik Özellikler | |

| Çekme Dayanımı | Yok |

| Kopma Uzama Oranı | Yok |

| Bükülme Modülü | Yok |

| Bükülme Gücü | Yok |

| Darbe Gücü | Yok |