Bambu PA6-CF, karbon fiber takviyeli bir PA6 (Nylon 6) filamentidir. Karbon fiber takviyesi, kuru ortamlarda önemli ölçüde yüksek sertlik ve mukavemet özellikleri sağlar ve olağanüstü ısı direnci ve darbe direncini korur. Diğer Bambu CF Filamentlerine benzer şekilde, bu olağanüstü mekanik özellikler onu kuru ortamlarda kullanılan fikstürler, kelepçeler, otomotiv ve mekanik bileşenler ve çeşitli yapısal ve mühendislik parçaları basmak için ideal bir seçim haline getirir.

Bambu yüksek performans filamentlerinin yeni üyesi olan PA6-CF, kuru ortamlarda üstün sertlik ve mukavemet özelliklerini korur, yük taşıyan yapısal bileşenlerin baskısı için mükemmeldir.

| Normal PA-CF | PA6-CF | İyileştirilmiş % | |

| Mukavemet (Eğilme Mukavemeti - XY, kuru hal) | 128 MPa | 151 MPa | %18 |

| Sertlik (Eğilme Modülü - XY, kuru hal) | 4420 MPa | 5460 MPa | %24 |

Bambu PA6-CF, baskılarınız için etkili titreşim direnci sağlayarak mükemmel darbe direnci sunar. Genellikle darbeye, çarpışmaya ve titreşime dayanması gereken modelleri basmak için kullanılır.

* PA6-CF baskıları 1 günden fazla nemli ortamda kaldığında daha dayanıklı olacaktır.

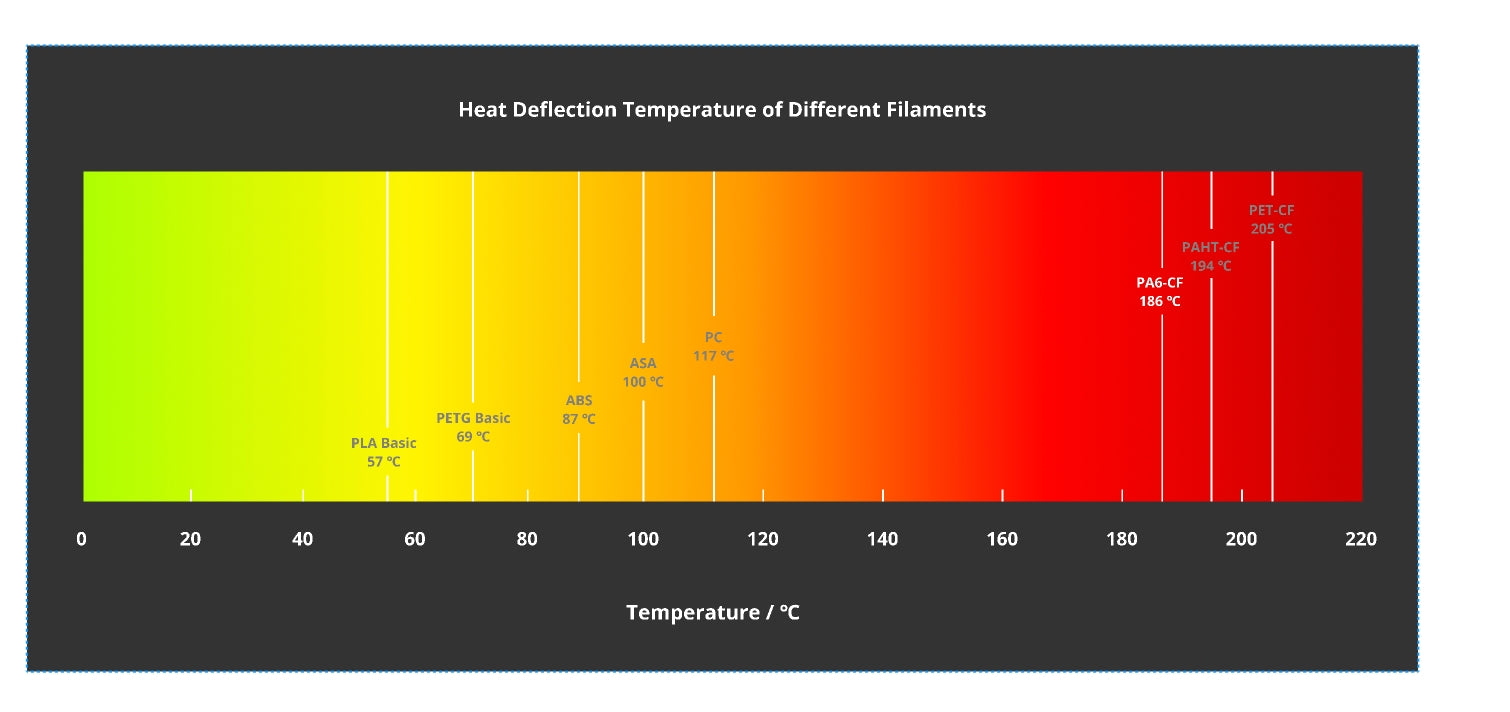

| Filament | PLA Temel | PETG Temel | ABS | ASA | Bilgisayar | PA6-CF | PAHT-CF | PET-CF |

| Isı Sapma Sıcaklığı / ℃ (0,45 MPa) | 57 ℃ | 69 ℃ | 87 ℃ | 100 ℃ | 117 ℃ | 186 ℃ | 194 ℃ | 205 ℃ |

Bambu Filament Rehberi'nde farklı filamentlerin karşılaştırması hakkında daha fazla bilgi edinin >>

| Normal PA6-CF | PA6-CF | PAHT-CF | |

| Kompozisyon | Naylon 6, karbon fiber | Naylon 6, karbon fiber | PA12 ve diğer uzun zincirli PA, karbon fiber |

| AMS Uyumluluğu | HAYIR | HAYIR | EVET |

| Kullanmadan Önce Kurutun | Gerekli | Gerekli | Gerekli |

| Baskı Hızı | < 100 mm/s | < 100 mm/s | < 100 mm/s |

| Yazıcı Türü | Muhafaza | Muhafaza | Muhafaza |

| Tokluk (Darbe Dayanımı - XY, kuru hal) | 35,7 kJ/m² | 40,3 kJ/m² | 57,5 kJ/m² |

| Tokluk (Darbe Dayanımı - XY, ıslak hal) | 65,4 kJ/m² | 57,2 kJ/m² | 62,3 kJ/m² |

| Mukavemet (Eğilme Mukavemeti - XY, kuru hal) | 141 MPa | 151 MPa | 125 MPa |

| Mukavemet (Eğilme Mukavemeti - XY, ıslak hal) | 67 MPa | 95 MPa | 115 MPa |

| Katman Gücü (Eğilme Gücü - Z, kuru durum) | 72 MPa | 80 MPa | 61 MPa |

| Katman Gücü (Eğilme Gücü - Z, ıslak durum) | 31 MPa | 45 MPa | 49 MPa |

| Sertlik (Eğilme Modülü - XY, kuru hal) | 4870 MPa | 5460 MPa | 4230 MPa |

| Sertlik (Eğilme Modülü - XY, ıslak hal) | 1890 MPa | 3560 MPa | 3640 MPa |

| Katman Yapışma (Darbe Dayanımı - Z, kuru hal) | 11,6 kJ/m² | 15,5 kJ/m² | 13,3 kJ/m² |

| Isıya Dayanıklı (HDT, 0,45 MPa) | 177 ℃ | 186 ℃ | 194 ℃ |

| Doymuş Su Emilim Oranı / % (25 °C, %55 RH) | 3.80 | 2.35 | 0,88 |

| Tavsiye edilen | Tavsiye Edilmez | |

| Yapı Plakası | Mühendislik Plakası, Yüksek Sıcaklık Plakası veya Dokulu PEI Plakası | Soğuk tabak |

| Sıcak uç | Sertleştirilmiş Çelik 0,4 / 0,6 (önerilen) / 0,8 mm | Paslanmaz Çelik Nozullu Hotend (tüm ebatlar) Sertleştirilmiş Çelik Nozullu Hotend (0,2 mm) |

| Zamk | Tutkal çubuğu Bambu Sıvı Yapıştırıcı | / |

| Önerilen Yazdırma Ayarları | |

| Baskı Öncesi Kurutma Ayarları | 80 °C, 8 - 12 saat |

| Baskı ve Konteynerin Nemini Koruma | < %20 RH (Kapalı, Kurutucu ile) |

| Nozul Sıcaklığı | 260 - 290 °C |

| Yatak Sıcaklığı (Tutkallı) | 80 - 100 °C |

| Baskı Hızı | < 100 mm/s |

| Fiziksel Özellikler | |

| Yoğunluk | 1,09 gr/cm³ |

| Vicat Yumuşama Sıcaklığı | 212 °C |

| Isı Sapma Sıcaklığı | 186 °C |

| Erime Sıcaklığı | 223 °C |

| Erime İndeksi | 6,8 ± 0,6 g/10 dak |

| Mekanik Özellikler | |

| Çekme Dayanımı | 102 ± 7 MPa |

| Kopma Uzama Oranı | %5,8 ± 1,6 |

| Bükülme Modülü | 5460 ± 280 MPa |

| Bükülme Gücü | 151 ± 8 MPa |

| Darbe Gücü | 40,3 ± 2,5 kJ/m² |

• Kurutma koşulları: 10 saat boyunca 80℃. PA6-CF neme karşı oldukça hassastır. Optimum baskı performansına ulaşmak için, kullanımdan önce ve depolamadan sonra daha fazla kurutma yapılması önerilir. Daha fazla ayrıntı için lütfen şuraya bakın: Filament kurutma talimatları WIKI'de.

• Bambu PA6-CF, suyu emdikten sonra mukavemet ve sertliğinde bir azalma yaşayacaktır, bu da mukavemet, sertlik ve boyutsal kararlılık için yüksek gereksinimleri olan baskı modelleri, özellikle ince ve uzun modeller için önerilmez. PA6-CF baskıları genellikle nemlendiklerinde daha sert ve darbelere, düşmelere ve çarpışmalara karşı daha dayanıklı hale gelir, model yüksek sertlik gerektiriyorsa baskıları önceden nemlendirebilir ve yumuşatabilirsiniz.

• Destekli bir model basarken, nemli ve yumuşamış haldeyken çıkarılmasının zor olmasını önlemek için destek yapısını 2 saat içinde çıkarmak gerekir. Desteği çıkarmak zorsa lütfen baskıları kurutun ve soğumasını bekleyin ve ardından desteği zamanında çıkarın.

• Baskıların yüzeyini boya, mum ve diğer su geçirmez kaplamalarla tamamen emdirmek, su emilimini engelleyebilir ve yumuşamasını önleyebilir.