KDV Dahil: 3.827,75 TL

Tükendi

Gelince Haber VerBambu PA6-GF, Cam Elyaflı Naylon 6 olarak da bilinir, yüksek performanslı mühendislik plastiklerinin ön saflarında yer alır. Olağanüstü güç, dayanıklılık ve boyutsal kararlılık sunmak üzere tasarlanmıştır. PA6-GF, diğer üst düzey mühendislik filamentleriyle karşılaştırıldığında daha uygun maliyetlidir.

Bambu PA6-GF, güçlendirilmiş cam elyafları sayesinde son derece güçlü ve dayanıklıdır; bu da onu yoğun kullanıma dayanıklı, bükülmeye veya kırılmaya karşı dirençli olması gereken baskılar için mükemmel bir seçim haline getirir.

* Not: Basılı parça neme maruz kaldıktan sonra daha iyi tokluğa ulaşır.

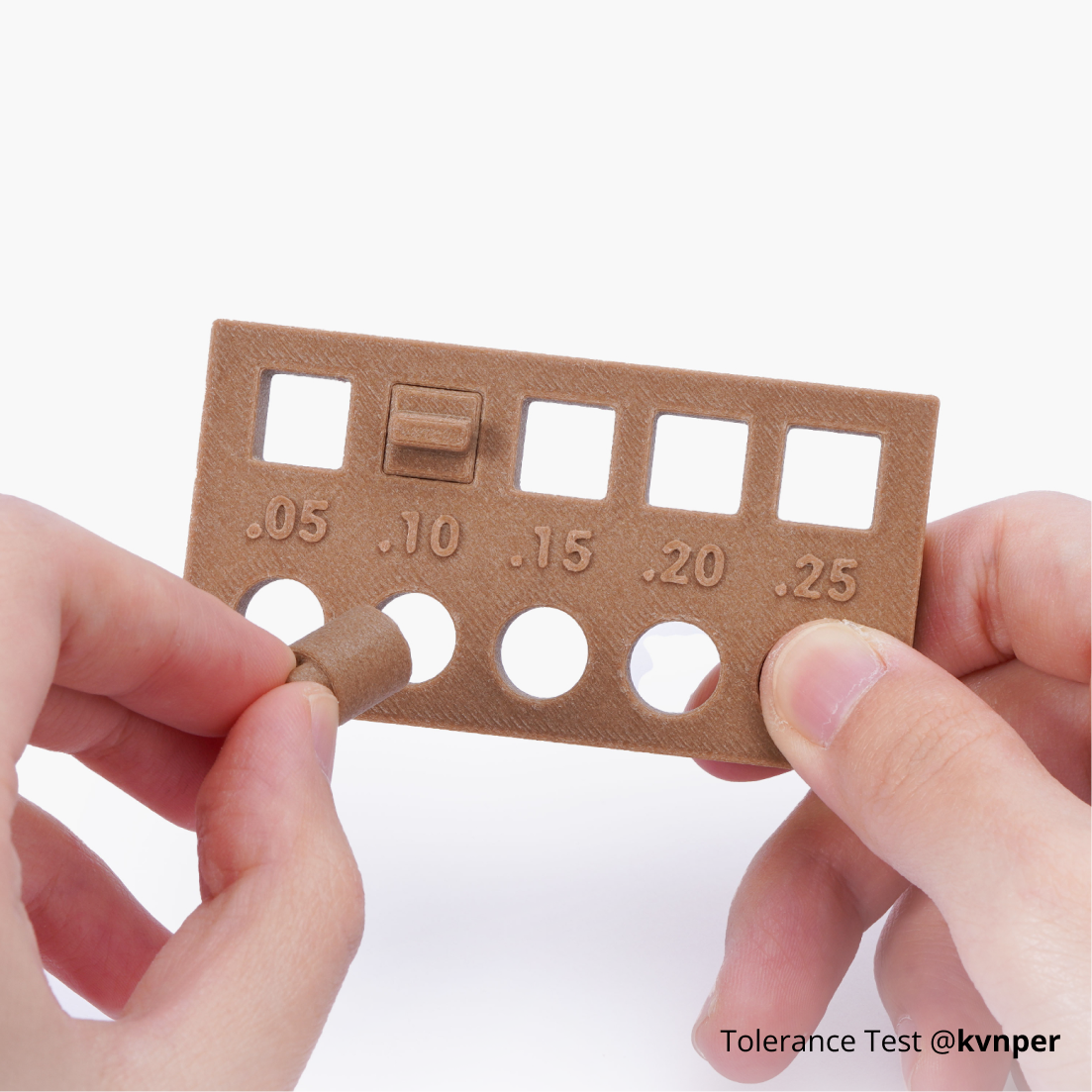

PA6-GF, cam elyaf takviyesi sayesinde benzersiz boyutsal kararlılığa sahiptir ve standart PA filamentlerine kıyasla eğilmeyi en aza indirir. En karmaşık geometrilerde bile hassas boyutlarda baskı yapın.

PA6-GF, yüksek ısı sapma sıcaklığına ve üstün boyutsal kararlılığa sahiptir ve bu sayede yüksek sıcaklıklarda bile mekanik özelliklerini koruyabilir. Bu, onu zorlu endüstriyel ve otomotiv uygulamaları için ideal hale getirir.

| Filament Türü | PLA Temel | ABS | Normal PA | Bilgisayar | PA6-GF | PA6-CF | PAHT-CF | PET-CF |

| Isı Sapma Sıcaklığı / ℃ (0,45 MPa) | 57 ℃ | 87 ℃ | 89 ℃ | 117 ℃ | 182 ℃ | 186 ℃ | 194 ℃ | 205 ℃ |

PA6-GF, kimyasallara, yağlara ve birçok solvente karşı mükemmel direnç göstererek zorlu ortamlarda uzun vadeli performans sağlar.

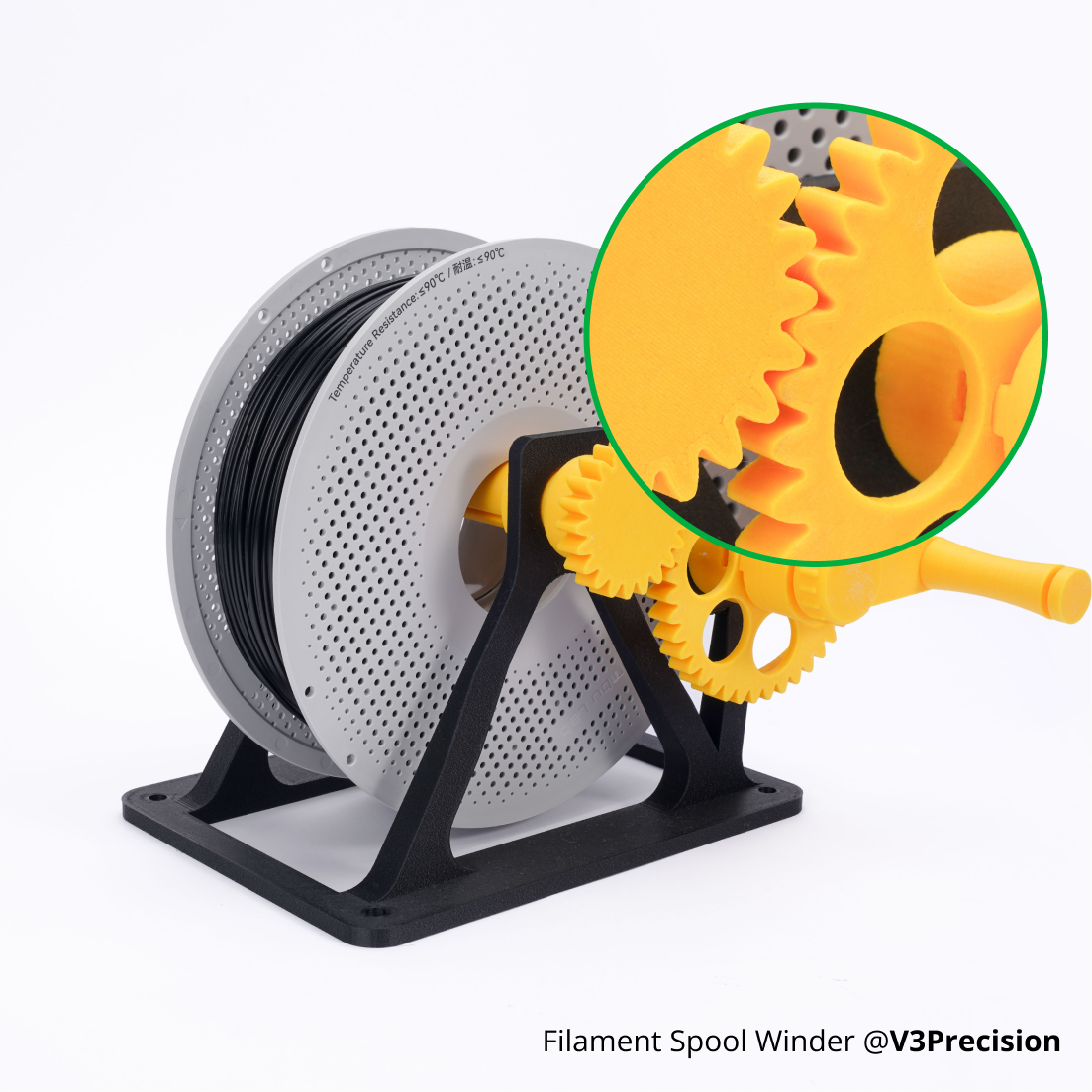

Bambu PA6-GF filamentleri Bambu AMS sistemiyle uyumludur, çok renkli baskıya hazırdır. Özel yüzey dokusu ayrıca katman çizgilerini bulanıklaştırarak pürüzsüz bir yüzey kalitesi sağlar.

| Renk | Hex Kodu | Görüntülemek |

| Beyaz | #EAEAE4 | |

| Sarı | #FFCE00 | |

| Kireç | #C5ED48 | |

| Mavi | #75AED8 | |

| Turuncu | #FF4800 | |

| Kahverengi | #5B492F | |

| Gri | #353533 | |

| Siyah | #000000 |

Tüm baskı parametreleri, AMS (Otomatik Malzeme Sistemi) üzerinden okunabilen RFID'ye yerleştirilmiştir.

Yükleyin ve yazdırın! Artık sıkıcı ayar adımları yok.

Bambu Filament Rehberi'nde farklı filamentlerin karşılaştırması hakkında daha fazla bilgi edinin >>

| PA6-GF | PA6-CF | PAHT-CF | |

| Kompozisyon | PA6, cam elyaf | PA6, karbon fiber | PA12 ve diğer uzun zincirli PA, karbon fiber |

| AMS Uyumluluğu | EVET | HAYIR | EVET |

| Kullanmadan Önce Kurutun | Gerekli | Gerekli | Gerekli |

| Baskı Hızı | < 130 mm/s | < 100 mm/s | < 100 mm/s |

| Yazıcı Türü | Muhafaza | Muhafaza | Muhafaza |

| Tokluk (Darbe Dayanımı - XY, kuru hal) | 27,2 kJ/m² | 40,3 kJ/m² | 57,5 kJ/m² |

| Tokluk (Darbe Dayanımı - XY, ıslak hal) | 55,8 kJ/m² | 57,2 kJ/m² | 62,3 kJ/m² |

| Mukavemet (Eğilme Mukavemeti - XY, kuru hal) | 120 MPa | 151 MPa | 125 MPa |

| Mukavemet (Eğilme Mukavemeti - XY, ıslak hal) | 71 MPa | 95 MPa | 115 MPa |

| Katman Gücü (Eğilme Gücü - Z, kuru durum) | 51 MPa | 80 MPa | 61 MPa |

| Katman Gücü (Eğilme Gücü - Z, ıslak durum) | 33 MPa | 45 MPa | 49 MPa |

| Sertlik (Eğilme Modülü - XY, kuru hal) | 3670 MPa | 5460 MPa | 4230 MPa |

| Sertlik (Eğilme Modülü - XY, ıslak hal) | 2120 MPa | 3560 MPa | 3640 MPa |

| Katman Yapışma (Darbe Dayanımı - Z, kuru hal) | 4,1 kJ/m² | 15,5 kJ/m² | 13,3 kJ/m² |

| Isı Direnci (HDT, 0,45 MPa, Kuru Hal) | 182 ℃ | 186 ℃ | 194 ℃ |

| Doymuş Su Emilim Oranı/%(25 °C, %55 RH) | 2,56 | 2.35 | 0,88 |

| Tavsiye edilen | Tavsiye Edilmez | |

| Yapı Plakası | Mühendislik Plakası, Yüksek Sıcaklık Plakası veya Dokulu PEI Plakası | Soğuk tabak |

| Sıcak uç | Sertleştirilmiş Çelik 0,4 mm / 0,6 mm (önerilen) / 0,8 mm | Paslanmaz Çelik Nozullu Hotend (tüm ebatlar) Sertleştirilmiş Çelik Nozullu Hotend (0,2 mm) |

| Zamk | Bambu Yapıştırıcı Çubuğu | Bambu Sıvı Yapıştırıcı |

| AMS ve AMS Lite | AMS ve AMS Lite | / |

| Önerilen Yazdırma Ayarları | |

| Baskı Öncesi Kurutma Ayarları | 80 °C, 8 - 12 saat |

| Baskı ve Konteynerin Nemini Koruma | < %20 RH (Kapalı, Kurutucu ile) |

| Nozul Sıcaklığı | 260 - 290 °C |

| Yatak Sıcaklığı (Tutkallı) | 80 - 100 °C |

| Baskı Hızı | < 130 mm/s |

| Fiziksel Özellikler | |

| Yoğunluk | 1,09 gr/cm³ |

| Vicat Yumuşama Sıcaklığı | 212 °C |

| Isı Sapma Sıcaklığı | 186 °C |

| Erime Sıcaklığı | 223 °C |

| Erime İndeksi | 6,8 ± 0,6 g/10 dak |

| Mekanik Özellikler | |

| Çekme Dayanımı | 102 ± 7 MPa |

| Kopma Uzama Oranı | %5,8 ± 1,6 |

| Bükülme Modülü | 5460 ± 280 MPa |

| Bükülme Gücü | 151 ± 8 MPa |

| Darbe Gücü | 40,3 ± 2,5 kJ/m² |